When we traveled to Uganda, we already brought ready-made prostheses with us. This served as a backup for potential technical delays and situations where we would need a prosthesis quickly. And indeed, the first prostheses that we used were from this collection. We fitted them to the personal stump-shape of the participant by thermoforming. To ensure an even better fit, we take the measurements of our participants in order to adjust the shaft size for newly printed prostheses. On May 11, we had the chance to fit our first truly tailor-made shaft to our participant Collin.

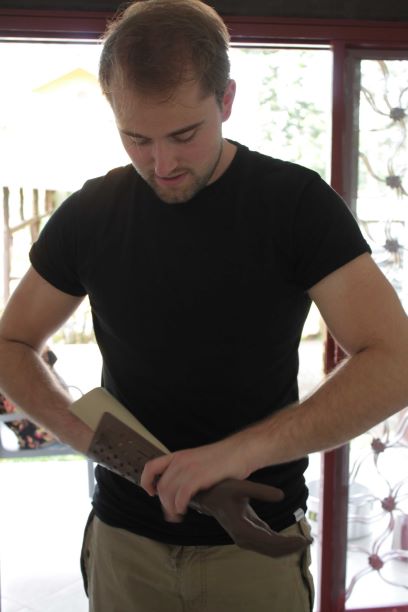

Kevin conducted a training on how to use the prosthesis in the everyday life. Fastening shoes is a good example for learning how to handle the new prosthesis. It is important to us that manufacturing and delivering our prostheses is not the last step in the cycle. In previous attempts of organizations to improve the prosthetic situation in African countries, a lot of effort was put towards handing out as many products as possible while neglecting the after-care. This results in the neglection of the device and an inability to properly use it. Therefore, we emphasize the importance of training and after-care to help amputees to benefit from our prostheses over the long term.

It was a pleasure to work with Collin and fitting his prosthesis. We are looking forward to his real-world-feedback!