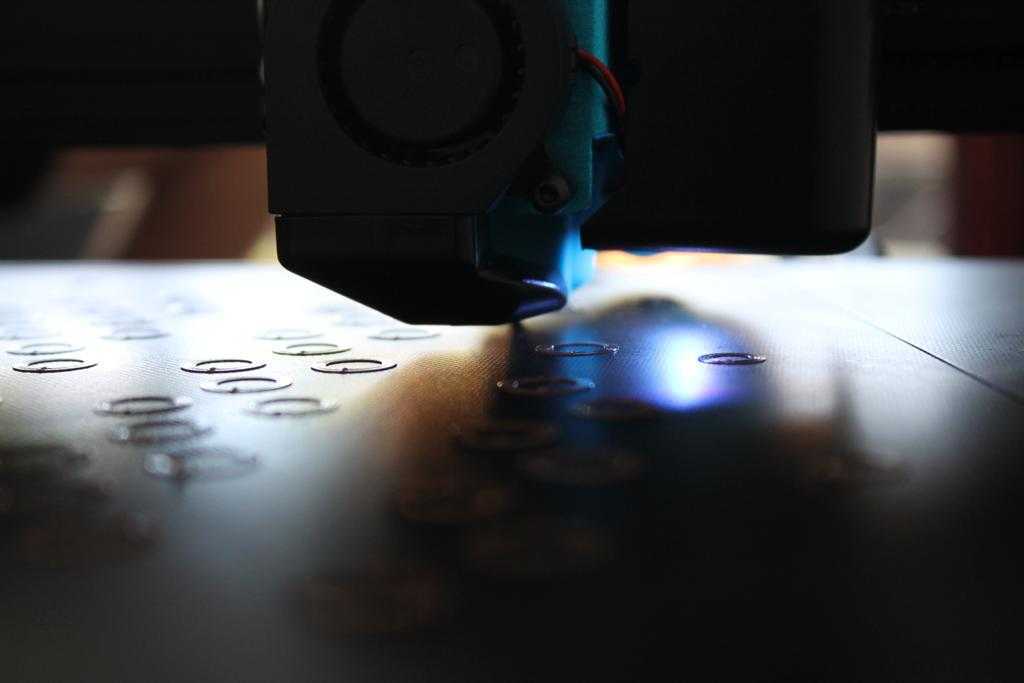

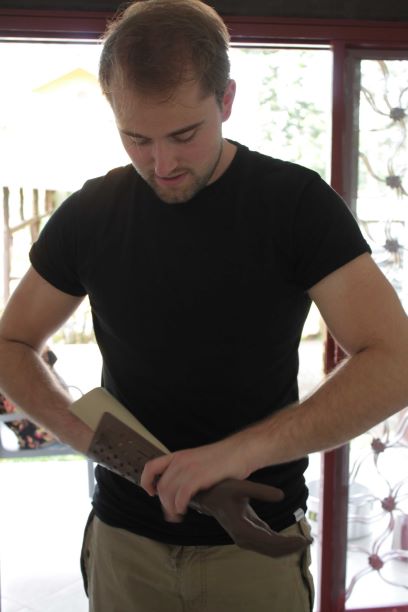

We saw our first patient already during our trip last year and were very excited to meet him again. Unfortunately he has some trouble with sensitive spots on his stump and phantom pain, which makes it hard for him to wear any prothesis at all. Nevertheless Johannes took his measurements and was able to start the first printing session after he solved some problems with the filament.

Here are some insights into the orthopedic workshop at CoRSU (https://corsuhospital.org/index.php): For example, at the moment they provide patients with a prosthesis after lower limb amputation, shoes for clumb foot and casts for broken bones or deformations.